Production

Production

Penta own manufacturing plant is equipped with machines supplied by European producers of proven quality and reliability. The latter are entirely engineered and made by Penta within its own workshops following defined and modern production procedures including laser cut, steel forming, welding and finishing followed by quality control, testing and delivery.

Penta own manufacturing plant is equipped with machines supplied by European producers of proven quality and reliability. The latter are entirely engineered and made by Penta within its own workshops following defined and modern production procedures including laser cut, steel forming, welding and finishing followed by quality control, testing and delivery.

Our range of products

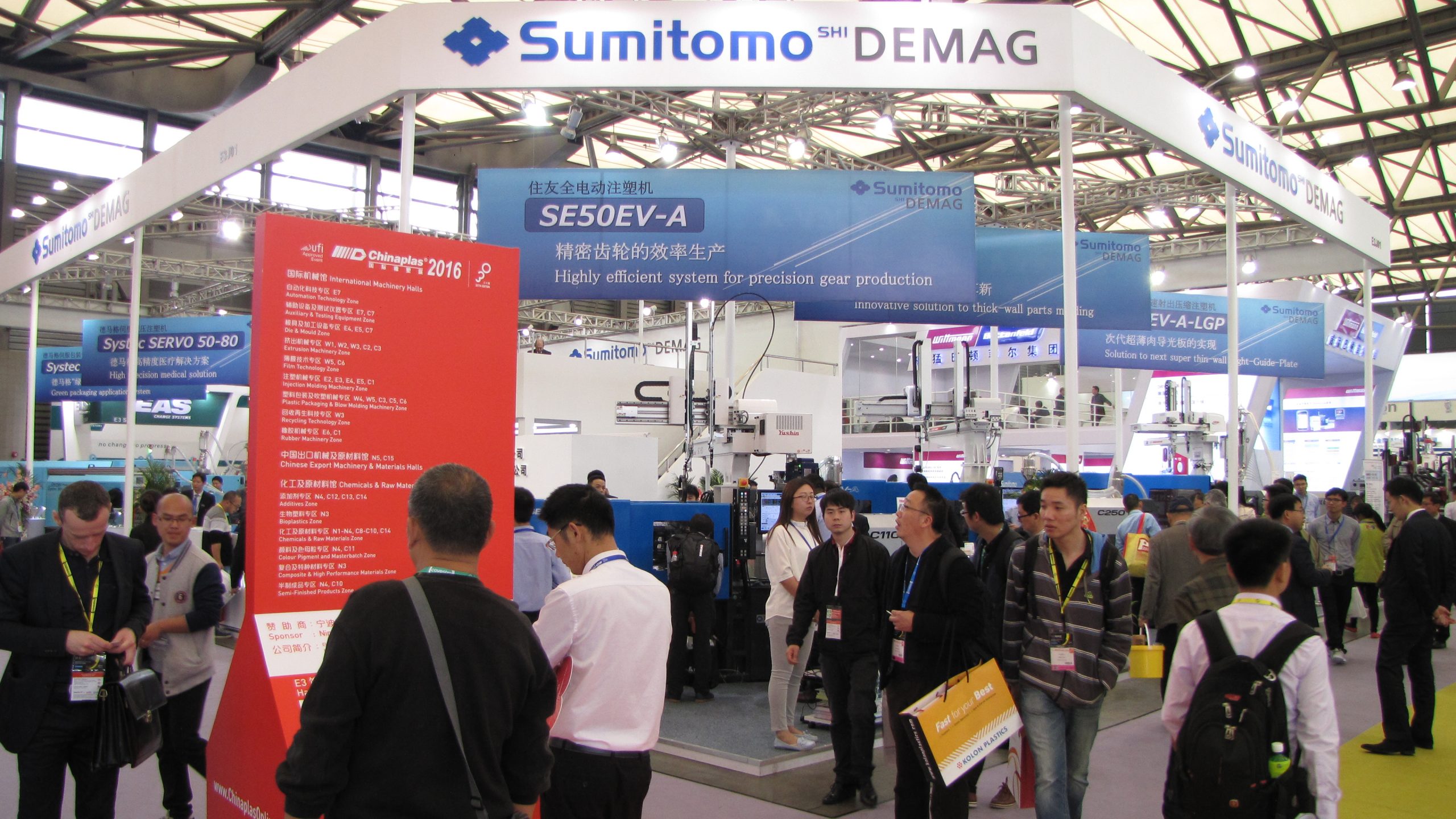

Sumitomo (SHI) Demag Global Sales Team — United in Expertise

From Asia to Europe, from America to the Middle East, we deliver the most advanced plastic injection molding machines tailored precisely to your production needs.

Let’s shape the future of plastics — together.