Flexible process for thin-walled and technical moulding

Injection compression moulding is a thermoplastic moulding process. It involves injecting the melt into a slightly open mould with simultaneous or subsequent compression. This is performed by the closing stroke of the machine or a coining core in the mould. The results is a lower cavity pressure when processing extremely thin-walled parts. The compression process also helps to minimise internal stress on moulded parts and improves dimensional accuracy; making it perfectly suitable for packaging applications or automotive parts, such as lighting applications.

Flexible process for thin-walled and technical moulding

Injection compression moulding is a thermoplastic moulding process. It involves injecting the melt into a slightly open mould with simultaneous or subsequent compression. This is performed by the closing stroke of the machine or a coining core in the mould. The results is a lower cavity pressure when processing extremely thin-walled parts. The compression process also helps to minimise internal stress on moulded parts and improves dimensional accuracy; making it perfectly suitable for packaging applications or automotive parts, such as lighting applications.

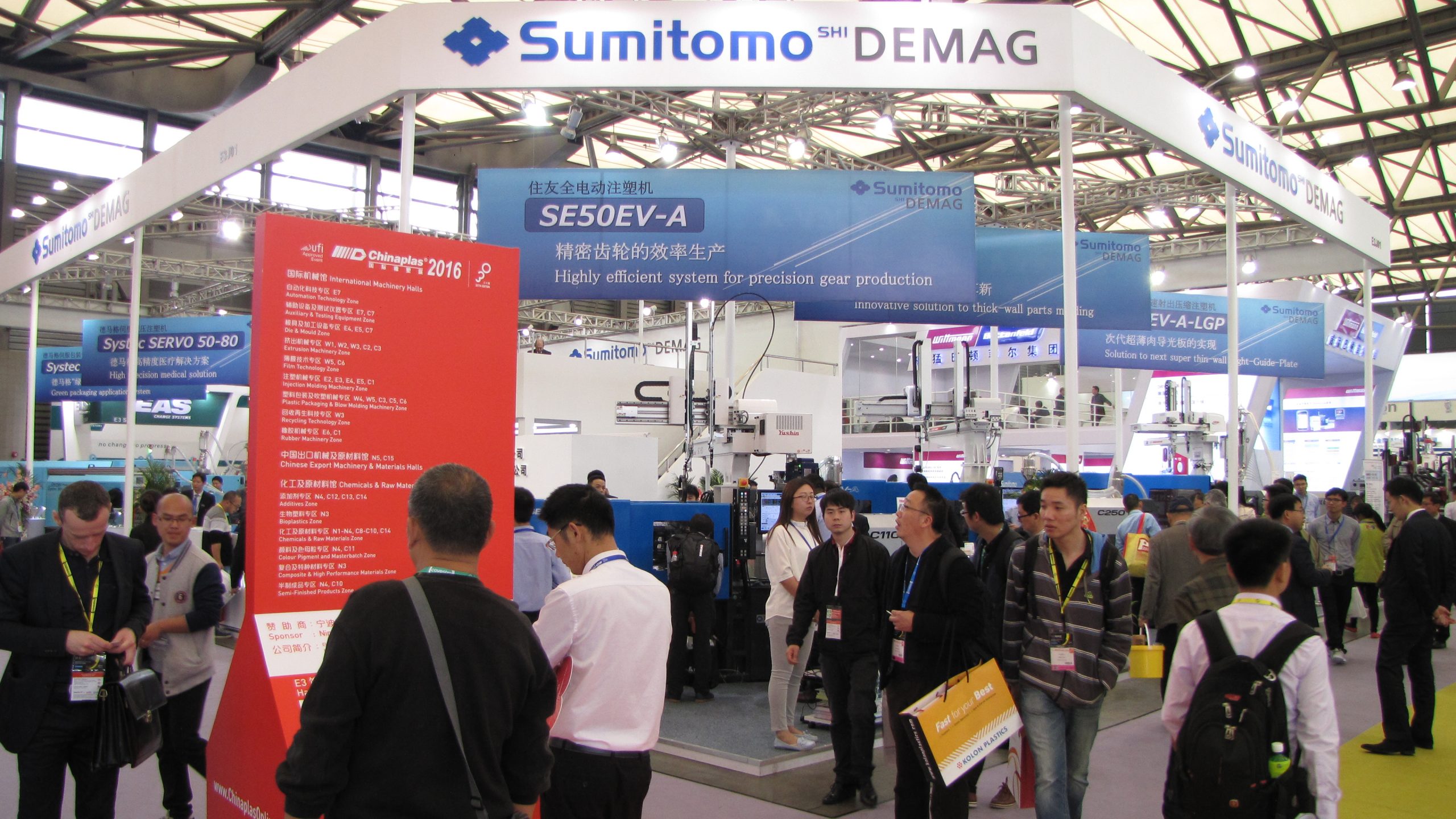

Sumitomo (SHI) Demag Global Sales Team — United in Expertise

From Asia to Europe, from America to the Middle East, we deliver the most advanced plastic injection molding machines tailored precisely to your production needs.

Let’s shape the future of plastics — together.